I-formwork isetshenziselwa ukwakhiwa kwekhonkrithi, isikhunta esenza ukhonkolo uthululwe futhi uvunyelwe ukuqina.Izinhlobo ze-formwork yekhonkrithi yokwakha incikeukhonkolo formwork materialskanye nezinhlobo zezinto zokwakha ze-formwork.

Izici ezijwayelekile zezinhlobo ezahlukene zama-formworks

Iqinile ngokwanele ukusekela umthwalo odingekayo wokuvala i-formwork.

I-formwork yekhonkolo kufanele iqinisekise ukugcinwa kuyimfihlo kanye nokungangeni kwamanzi kokwakhiwa kwe-formwork.

Kulula ukususa amamojula we-formwork njengoba evala ukhonkolo.

I-formwork kufanele ibe lula ngokwanele ukuthutha.

Izinhlobo ezivamile zezinto zesistimu ye-formwork ezisetshenziswa ekwakheni ukhonkolo njengoba ngezansi.

I-Timber Formwork

Ama-formworks amapulangwe azothatha isimo esizungeze indawo evulekile.Izingodo ezisetshenziselwa ukuvala ifomu konke okudingekayo ukuhlanza ingaphezulu le-modular ukuze kube lula ukuvala kamuva ekwakheni.Ibuye ibe nezinzuzo ezimbalwa ngaphezu kwezinye izinhlobo zezinto zokwakha.

Izindleko Eziphansi

Ama-formworks e-Timber achitha izindleko eziphansi kuphrojekthi ye-formwork kakhonkolo, I-formwork yensimbi inenani eliphakeme ngokwemibandela ehlobene.Ngoba izingodo zinokutholakala okwengeziwe kanye nezindleko zokukhiqiza ezishibhile.

Ukuphatha Kalula

Labo abasha abaqala ukwakha ama-formworks ngokuvamile bazokhetha izingodo njengamathuluzi okuqala, awadingi amathuluzi akhethekile noma izinga elithile lomsebenzi wokwakha.Izinkuni zivame kakhulu ekuphileni futhi zibiza kancane kunezinye

Ukubukeka Okungcono

I-formwork yamapulangwe ingenziwa ibukeke kangcono ngokwakhiwa kwezakhiwo zamapulangwe ezenziwe ngaphambili.Upende namafutha nakho kungafuthwa esakhiweni ukuze kunwetshwe ukuphila kwaso.

I-Plywood Formwork

I-resin plywood ixhunywe kuhlaka lwamapulangwe, futhi ibe amaphaneli e-formwork yobukhulu obudingekayo.Isetshenziselwa ikakhulukazi ukushelela, ukuhlobisa kanye nokwenza ama-linings.I-plywood formwork inezinzuzo ezilandelayo:

1. I-plywood shuttering ingasetshenziswa kabusha izikhathi eziningi, iphaneli ingasuswa futhi ihlanganiswe ngokuvumelana nezidingo zakho.

2. Ukusebenzisa umshini kungenza usayizi ojwayelekile we-plywood formwork futhi ulungiswe kalula endaweni.

3. Isilinganiso esiphansi sesisindo-amandla esingenza i-formwork yekhonkrithi ibe namandla aphezulu kanye nesisindo esilula.

4. Isevisi enamandla eyenziwe ngokwezifiso, uhlelo lwe-plywood formwork lungahlinzeka ngezinhlobo eziningi zokumbondelana nosayizi ngokwezidingo zakho.

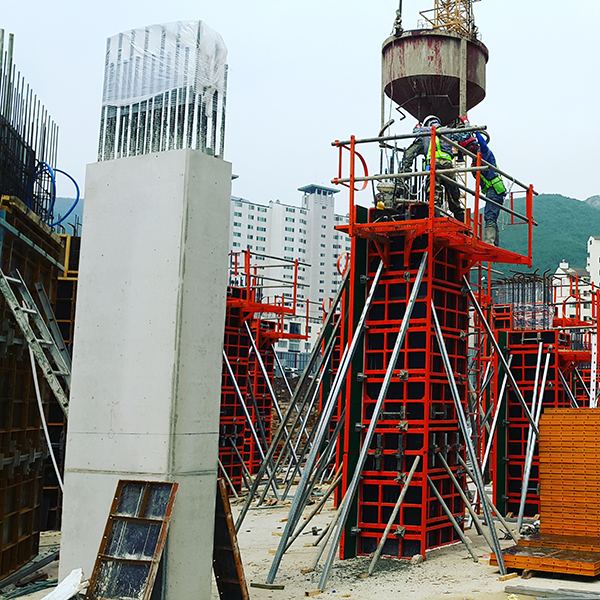

Insimbi Formwork

Insimbi iyinto enhle yokwenza i-formwork ekwakhiweni, ngoba ayigobi ngisho noma ilayisha isisindo esikhulu, i-Steel formwork of shuttering ingagcina inani elikhulu likakhonkolo, elilungele ukwakhiwa kwensimu.

1. Ngenxa yezinto zayo, ukwakhiwa kwe-steel formwork kuhlala isikhathi eside kunokhuni, futhi akulula ukuguqula nokulimaza.insimbi ingasetshenziswa kabusha, ngakho ithandwa kakhulu emakethe.

2. Ubuso be-formwork yensimbi ye-concrete ye-precast ayidingi ukucutshungulwa, ngoba ubuso bushelelezi kune-formwork yokhuni ngenxa yezizathu ezibonakalayo.

3. I-Steel shuttering ayimumbi umswakama kakhonkolo njengokwakhiwa kwezinkuni.Ngakho-ke, i-formwork yensimbi yokhonkolo ingaqinisekisa ikhwalithi engcono kakhulu.

4. Insimbi ithambile kakhulu futhi ilungele izakhiwo eziyisilinda noma eziyindilinga.Amaphaneli e-steel formwork angenziwa ngokwezifiso nganoma yiziphi izinhlobo zomumo we-modular noma usayizi.

5. I-steel formwork kulula ukuyisusa nokuyifaka esizeni.

Aluminium Formwork

I-Aluminium formwork iwuhlobo olusha lwempahla yokwakha.Ibiza futhi yakhelwe izingxenye zokwakha.I-Aluminium formwork system ifakwa ngokushesha, iphephile, ayihambisani nemvelo.I-Aluminium futhi inekhwalithi enhle kakhulu yefomu lokhonkolo.Ingaqedwa ngokuphelele ngaphandle kokusebenzisa i-stucco, egcina izindleko.

1. Uhlelo lwe-aluminium formwork lunganciphisa isikhathi sokwakha.Isitezi esisodwa sefulethi singakhiwa kusetshenziswa izinsuku ezine kuphela ngokuya ngemidwebo enqunyiwe yokuklama.

2. I-Aluminium formwork inokusimama okuhle kanye nekhono elihle lokuthwala.Ngoba zonke izingxenye zayo zihlangene kusuka epuleti lensimbi ye-alloy zibe luhlaka, ngakho-ke inokumelana okungcono kwesisindo kunokwakheka kwezinkuni.

3. I-Aluminium formwork ifana kakhulu ne-steel formwork.Umehluko omkhulu ukuthi i-aluminium incane kakhulu kunensimbi, ngakho-ke ukwenza ukuvala ekwakhiweni kube lula.Lokhu kuyinzuzo yabo eyinhloko ngaphezu kwe-formwork yensimbi.Le formwork iyonga ukusetshenziswa kakhulu ngesikhathi sokwakhiwa.

4. I-Aluminium inamandla aphansi kunensimbi, ngakho-ke kufanele icatshangelwe ukuthi ithinteke ngaphambi kokusebenzisa i-aluminium formwork.Futhi uma imojula yezinto zokuvala yakhiwe, akukho ukuguqulwa okungenzeka.

Plastic Formwork

Uhlelo lwe-plastic formwork luwuhlelo olusebenzayo lokwakha, okuyindlela enhle kakhulu yokonga izindleko zokukhiqiza.Ihlanganisa i-formwork yodonga, i-cylindrical formwork, i-formwork yekholomu yesikwele, kanye nefomu eliyisicaba.

1. Ifomu lepulasitiki elinamaphaneli angama-modular osayizi wezindonga, amakholomu kanye nemishayo.

2. Iphaneli ye-formwork yepulasitiki ilula futhi isibambo esikhuphuka ngokushesha, yonga izindleko zabasebenzi.

3. I-Plastic modular surface ibushelelezi futhi ithambile.

4. I-formwork yepulasitiki iyindlela enhle yomshini wokwenza ukhonkolo we-foam we-3-in-1.

5. Isebenziseka kabusha, iyonga kakhulu.

Indwangu Formwork

I-formwork yendwangu ingasetshenziswa ngokukhonkolo ukukhiqiza izakhiwo ze-formwork zomumo nobukhulu obuhlukahlukene.Kusukela kumakholomu nemishayo kuya ezindongeni, osinki, ifenisha kanye nohlu lwezesekeli.

Ingaqinisekisa umnotho kanye nokuqina kwezakhiwo zikakhonkolo.Okwesibili, ayinqunyelwe ngokuklama, futhi ingasetshenziswa kabanzi emishayo, amakholomu nezindonga.

Ama-stencil endwangu ahlinzeka ngendlela eyingqayizivele yokubumba futhi imingcele yesici ikhona yonke indawo.isikhunta sakhiwe ngamashidi endwangu enezimbotshana ezifana neyiloni, i-polyester, i-polypropylene, njll. Umumo oklanyelwe wakhiwe ngokucindezela kokhonkolo omanzi.

Naphezu kwezinhlobonhlobo zemiklamo nokusetshenziswa kwamafomu okhonkolo we-precast, izinqumo eziningi zephrojekthi, azikho izinketho ezingcono kakhulu, kuphela ezilungele wena.Isifanekiso esifanelana kangcono nephrojekthi yakho sizohluka ngokuya ngedizayini yakho yezakhiwo.

Isikhathi sokuthumela: Dec-27-2019