Formwork is used in concrete construction, the mould which make the concrete is poured and allowed to harden. Types of concrete formwork for construction depends on concrete formwork materials and types of formwork construction element.

Normal features of different types of formworks

Enough firm to support the load needed for the formwork shuttering.

Concrete formwork should ensure the confidentiality and waterproofness of the formwork construction.

It is easily to remove formwork modules as they are concrete shuttering.

The formwork should be light enough for transport.

The common types of formwork system material used in concrete construction as below.

Timber Formwork

Timber formworks will take the form surrounding an open cavity. The timber using for shuttering formwork all needed to clean the surface of the modular to facilitate later shuttering in construction. It also has several advantages over other material types of formwork.

Lower Cost

Timber formworks spending a lower cost in concrete formwork project, The steel formwork have a higher price in relative terms. Because timber has more availability and cheaper production costs.

Easier Handling

Those newer who are beginning building construction of formworks typically will choose timber as the first tools, it doesn’t require any special tools or a particular level of construction experience. Wood is more common in life and it costs lower than others

Better Appearance

Timber formwork can be made the better appearance with construction of prefabricated timber structures. Paint and oil also can be sprayed on the building to extend its life.

Plywood Formwork

The resin plywood is attached to the wooden frame, and become the formwork panels of the required size. It is mainly applied for sheathing, decking and form linings. Plywood formwork has the following advantages:

1. Plywood shuttering can be reused many times, the panel can be removed and spliced according to your requirements.

2. Using a machine can make a standard size for plywood formwork and easily fixed in position.

3. Low weight-strength ratio which can make the concrete formwork have higher strength and with lighter weight.

4. Powerful customized service, plywood formwork system can provide many kinds of overlays and sizes according to your requirements.

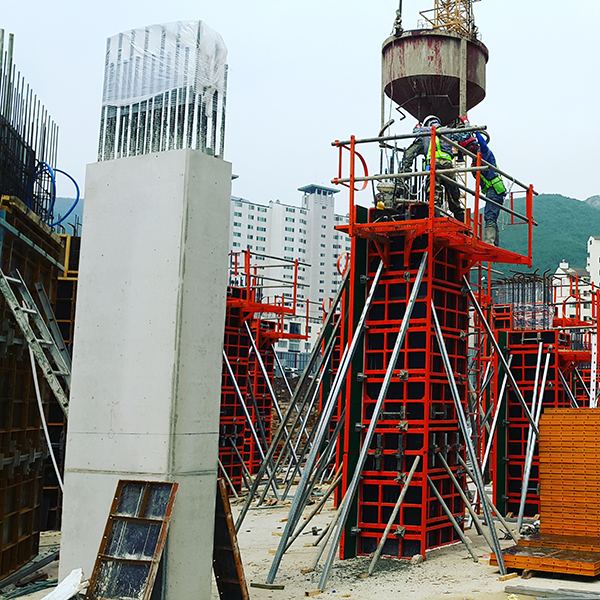

Steel Formwork

Steel is a good material for making formwork in construction, because it does not bend even if load big weight, Steel formwork of shuttering can store a large amount of concrete, which is convenient for field construction.

1. Because of its own material, steel formwork construction is more durable than wood formwork, and it is not easy to deform and damage. steel can be reused, so it is more popular in the market.

2. The surface of the precast concrete steel formwork does not need processing, because the surface is smoother than the wooden formwork because of material reasons.

3. Steel shuttering does not absorb the moisture of concrete as the wood formwork. Therefore, the steel formwork for concrete can guarantee the best quality.

4. Steel is more malleable and suitable for cylindrical or round structures. Steel formwork panels can be customized with any types of modular shape or size.

5. Steel formwork is easier to remove and install on site.

Aluminum Formwork

Aluminum formwork is a new type of building material. Cost-effective and designed for building components. Aluminum formwork system is fast installation, material safe, environmentally friendly. Aluminum also has excellent concrete formwork quality. It can be completely finished without using stucco, which saves costs.

1. The aluminum formwork system can reduce the construction time. One floor of an apartment can be built only using four days that according to the determined design drawings.

2. Aluminum formwork has good stability and excellent bearing capacity. Because all its components are assembled from a metal alloy plate into a frame, so it has the better weight resistance than wood formwork.

3. Aluminum formwork is very similar to steel formwork. The mainly difference is that aluminum is less dense than steel, so making the shuttering in construction lighter. This is their main advantage over steel formwork. This formwork is economical using extensively during construction.

4. Aluminum has a lower strength than steel, so it must be considered for affect before using aluminum formwork. And once the module for shuttering material is built, no changing is possible.

Plastic Formwork

Plastic formwork system is an effective building formwork system, which is an excellent way to save manufacturing costs. It includes wall formwork, cylindrical formwork, square column formwork, and flat formwork.

1. Plastic formwork with modular sized panels for walls, columns and beams.

2. Plastic formwork panel is lighter and quick-mounting handle, saving labor costs.

3. Plastic modular surface is smoother and flatter.

4. Plastic formwork is a good way for 3-in-1 foam concrete forming machine.

5. Reusable, more economical.

Fabric Formwork

Fabric formwork can be used with concrete to produce formwork structures of various shapes and sizes. From columns and beams to walls, sinks, furniture and a range of accessories.

It can ensure the economy and durability of concrete structures. Secondly, it does not limit by design, and can be widely used in beams, columns and walls.

Fabric stencils provide a unique molding method and feature parameters are universal. molds are made up of porous fabric sheets such as nylon, polyester, polypropylene, etc. The designed shape is formed with the pressure of the wet concrete.

Despite the variety of designs and uses of precast concrete forms, the most project decisions, there is no best options, only the one that is more suitable for you. The template that best fits your project will vary based on your architectural design.

Post time: Dec-27-2019