The terms formwork and shuttering are both used to describe the process of making the molds in which concrete is poured and contained until it hardens. Shuttering refers to the method of forming the mold using plywood while formwork is more of a broader term that’s used to denote the process of creating a mold using a variety of materials. Both formwork and shuttering accomplish the same task, with the main difference being the materials used to accomplish the task. Sometimes there’s no differentiation between the two terms, but in most cases, shuttering is considered to be a type of formwork.

Projects of different sizes will often need to employ both formwork and shuttering techniques. Large-scale construction projects are most likely to use a variety of formwork types. But in most cases, shuttering will be the most popular option since it’s easy to use and can be built in a way that allows for significant amounts of concrete to be poured at a go. Furthermore, using plywood to make shuttering is much cheaper, especially considering that plywood can be recycled or reused. However, when it comes to shuttering and formwork, a special grade of plywood will be necessary. The material should be water-resistant since most concrete projects are done outdoors.

As earlier mentioned, the difference between formwork and shuttering is very small. When selecting formwork and shuttering, the type of concrete and temperature of the pour are important considerations as they both affect the pressure exerted. The formwork sides must be capable of resisting the hydrostatic pressure of the wet concrete which will diminish to zero within several hours depending on the rate of setting and curing. The formwork base or soffit must be capable of resisting the initial dead load of the wet concrete and the dead load of the dry set concrete. High quality workmanship and inspection are necessary to ensure a high standard and appearance of the resulting concrete structure.

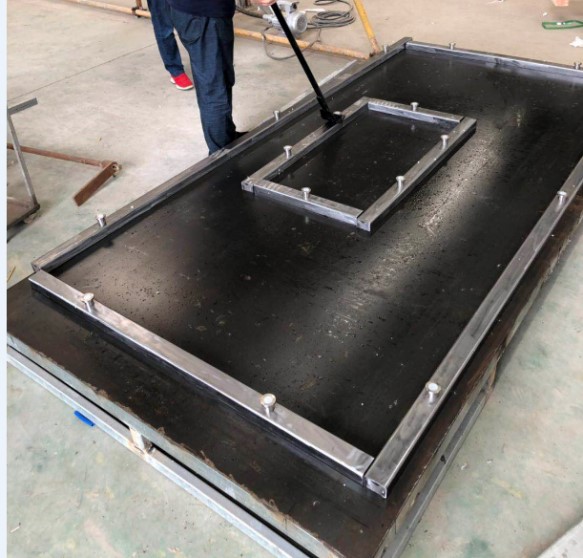

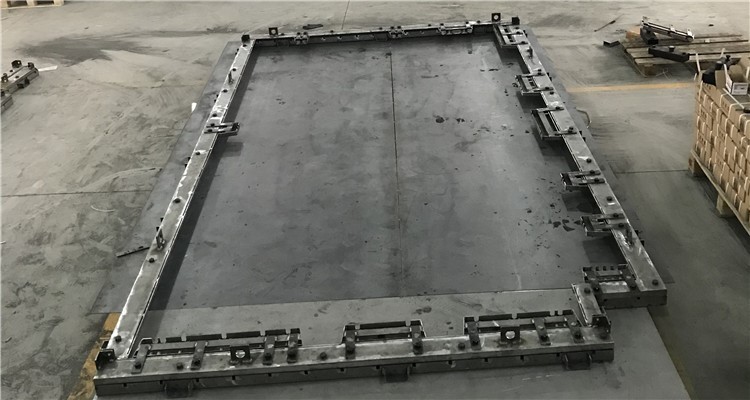

In precast concrete production, both shuttering and formwork in its various forms will be supported by clamps. Magnetic clamps are widely used by the precast concrete plant.

Post time: Jul-13-2020