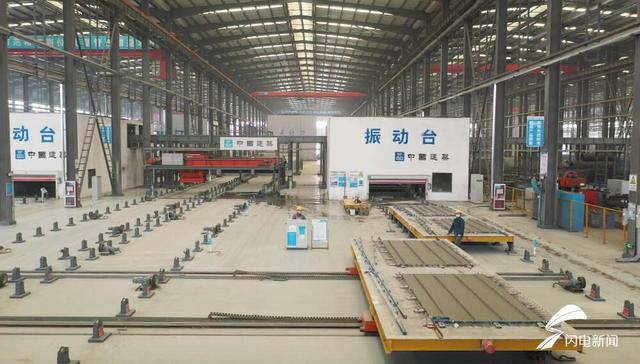

In the prefabrication and construction workshop of China Construction Green Industrial Park, workers are carrying out steel bar binding operations. It only takes one day for a prefabricated laminated plate to be designed and produced before leaving the factory.

From production to delivery, laminated boards require nine steps, including concrete steaming curing, steel bar binding, and curing. The daily output of a single production line is 3000 square meters. Taking an ordinary 30-story residential building as an example, the amount of laminated version required for the building can be fully produced in five days by a single production line.

Compared to traditional construction mode, the main structural components of prefabricated buildings are all modular produced on the assembly line, leaving out the complex processes of traditional housing construction series, reducing on-site construction personnel, and maintaining the cleanliness of construction. Compared to traditional projects, the construction period can be shortened by 3-4 months.

It is understood that prefabricated buildings can use heating, ventilation, energy conservation, passive energy conservation, and other methods to achieve energy conservation and emission reduction. In HVAC design, designers apply prefabricated building construction technology, which can not only improve the heating and ventilation conditions of buildings, but also reduce the energy consumption of indoor central air-conditioning systems. At the same time, construction personnel can also reasonably configure the split central air conditioning system according to the climate characteristics of the construction area, thereby effectively reducing system energy consumption. On the other hand, in terms of passive energy conservation, non mechanical and electrical equipment interventions are used to reduce building energy consumption. In the upstream architectural planning and design, construction personnel can reduce building energy consumption through reasonable layout of building orientation, setting up shading facilities and building envelope structures, natural ventilation design, and other measures to achieve green, environmental protection, and energy conservation

With the continuous development of the construction market, architectural engineers are also designing more and more personalized buildings, which makes it difficult to unify standards for design and construction. Using the EPC production mode can open the entire chain of upstream design, midstream production, and downstream assembly.

The designer said, “We vigorously promote EPC. In view of the contradiction between the diversity of design standards and the standardization of prefabricated components, taking Shandong Construction Green Industrial Park as an example, as the core of prefabricated buildings, by intervening in the front-end design, engineers can conduct a standardized decomposition of the design, providing a strong guarantee for the rapid construction and efficient performance of the entire project.”.

Post time: Mar-31-2023